Search This Supplers Products:Binding MachineBinding machinePerfect binderPaper cutterLaminating MachineShredder

4 in one multifunctional binding machine with patent (SUPER4&1)

- FOB Price

US $1800.02 - 5 piece

US $1500.06 - 10 piece

- group name

- Multifunction binding machine

- Min Order

- 2 piece

- brand name

- SUPU

- model

- SUPER4&1

- Nearest port for product export

- NINGBO, SHANGHAI

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

- Export mode

- Have the independent export and import right

- update time

- Fri, 30 Jan 2026 18:54:21 GMT

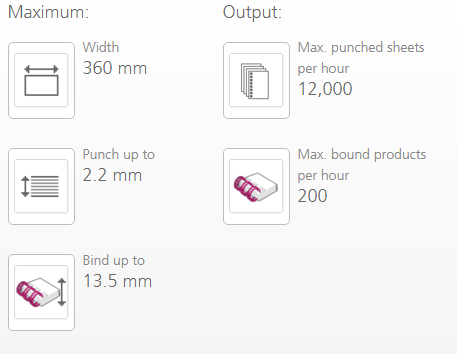

Paramtents

Power Electricity

Width 500mm

Pitch on request

Hole type on request

Punching thickness 25—35sheets

Binding Thickness 120—400sheets

Number of punch pins depending on the die

Disgagement punch pins depending on the die

Packging & Delivery

- 75cm x65cm x60cm

-

Min Order2 piece

Briefing

Die punching amchine

Easy to operate

Revolver machine

International patent design

Certification:CE CETL CB SAA R

Easy to operate

Revolver machine

International patent design

Certification:CE CETL CB SAA R

Detailed

3:1 pitch entry-level office manual punching and binding machine designed for regular use in a small to medium sized office.

- *Binds up to 135 sheets

- *Closure control guarantees easy ring wire closure for perfect presentations every time

- *Special hardened punch pins for long lasting life

- *Staggered punching pins for better punching

- *For formats: A5, A4

- *Adjustable side lay for perfect punching registration

- *Easy to empty sliding waste tray

- *Measures the document or ring wire size

- *Parallel adjustment guarantees a perfect bind every time

- *Heavy duty construction & compact design

All performance outputs are based on 80 gsm paper and may vary depending on the product type, the working environment and the operator. For best punching results we recommend a paper thickness of 1.5 - 2.0 mm. (1) Dependent on machine type.