Search This Supplers Products:Binding MachineBinding machinePerfect binderPaper cutterLaminating MachineShredder

Heavy duty Paper hole punching machine SUPER600

- group name

- more

- Min Order

- 1 piece

- brand name

- SUPU

- model

- SUPER600

- Nearest port for product export

- NINGBO, SHANGHAI

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

- Export mode

- Have the independent export and import right

- update time

- Sat, 28 Feb 2026 11:16:57 GMT

Paramtents

color white+black+orange

Material All metal

Punching width 600mm (24 inch )

Punching thickness 5mm(35-50sheets)

Punching material Paper or carton board

Punching die material Mould steel

Operation mode Electric by foot pedal

Changing of dies Yes

Closing double wire From 5mm to 32mm

Machine weight 260kgs

Packging & Delivery

-

Min Order1 piece

Briefing

changing of dies is quick and easy

Can closing double wire

Detailed

Heavy duty Paper hole punching machine SUPER600

SUPER600 heavy duty paper punching machine is a semi-automatic electric paper punching machine which can be used in industry, notebook producing factory ,enterprise and large organizations with firm design.

SUPER600 has advanced motor reducer and special-made mechanical clutch. Motor can run continuously for 24 hours and punching controlled by foot pedal which is easy and safe for operation.

Interchangeable die is easy and fast, which can punch various holes.Closing double wire is also available by changing punching dies into closing die and can close any size of double wire .

Punching depth margin can also adjustable from 2mm to 6mm which make this machine perfect .

SUPER600 will be your necessary assistant in your work ~

Specificatin :

Punch thickness:5 mm

Wire closing: 3/16"1 1/4"(5.532 mm)

Punch width: 600mm

Adjustable side margin: 3-6mm

Punch speed: 60times/minute

Power voltage: AC220V,50HZ

Dimension: 1000x640x1110mm

Machine weight: 270KG

Motor power: 1.5KW

Can 24 hour continous working

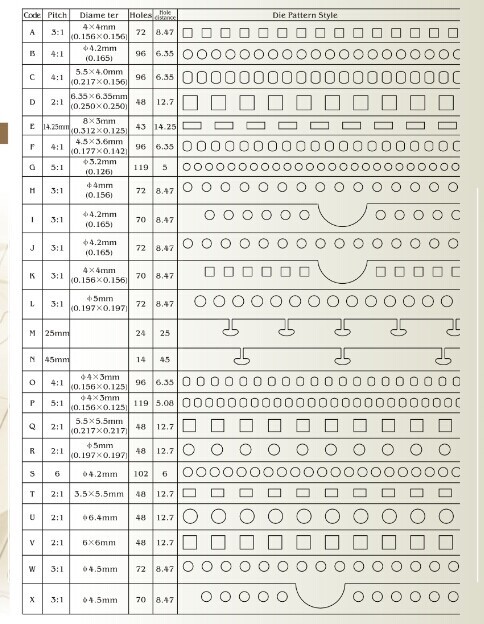

Please note: the punching dies are exchangeable and can be made according to customers' need.

How to change dies

1.First, switch off the machine, open the cover,loose the fixed screws of it ,and take out cover upwards.

2.Second, insert two cushions between fixed board and punching bars A at eachside, to make sure that the blade of the punching pins are not abraded.

3.Third, Loose the hexagon screws A and B

4. Assemble the red bracket to the die andthen pull out the die by taking the bracketat the right side and keep it in a save place.

5.When installing, push the new dies along with the die guide slot and install. After that, fasten the hexagon boltA and hexagon bolt B and disassemble the red handle.

6. Turn the hexagon bolt A with tools in anticlockwise to take out of the cushion. After that, turn the hexagon nut A in anticlockwise once again for one or two circles to

check whether the machine can work normally. If yes ,start to work ,

How to disengage punching pins:

Depending on paper size and punching pattern, it can disengage the punching pins . But do not disengage more than 4 pins . The procedures are:

1.Switch off the machine,loose hexagon bolt and take away the upper mode bar .

2.Knob the punching pins upwards staring from the down mode direction by using the copper bar. Then keep the pins for future use and cover the upper-mode bar, finally fasten the hexagon bolt.

How to Installe methods of wire closer. (with a accompanying drawing)

1.The mold for wire closing consists of pressingbar and down-mold board, which are fixed to the supporting girders and bases respectively, with magnet inside.

The procedures are as follows:

1. There are three adjustable screws on the pressing bar . Then insert the adjustable screws into the three holes from bottom to up. After that, add the cushion ,tight the adjustable screws .Then assemble the Screw cap and knob .

2. Install the down mold and push it into the guiding slot, then fasten the bolt.

Punching die pattern

CE approved

Big promition in middle year