Search This Supplers Products:Binding MachineBinding machinePerfect binderPaper cutterLaminating MachineShredder

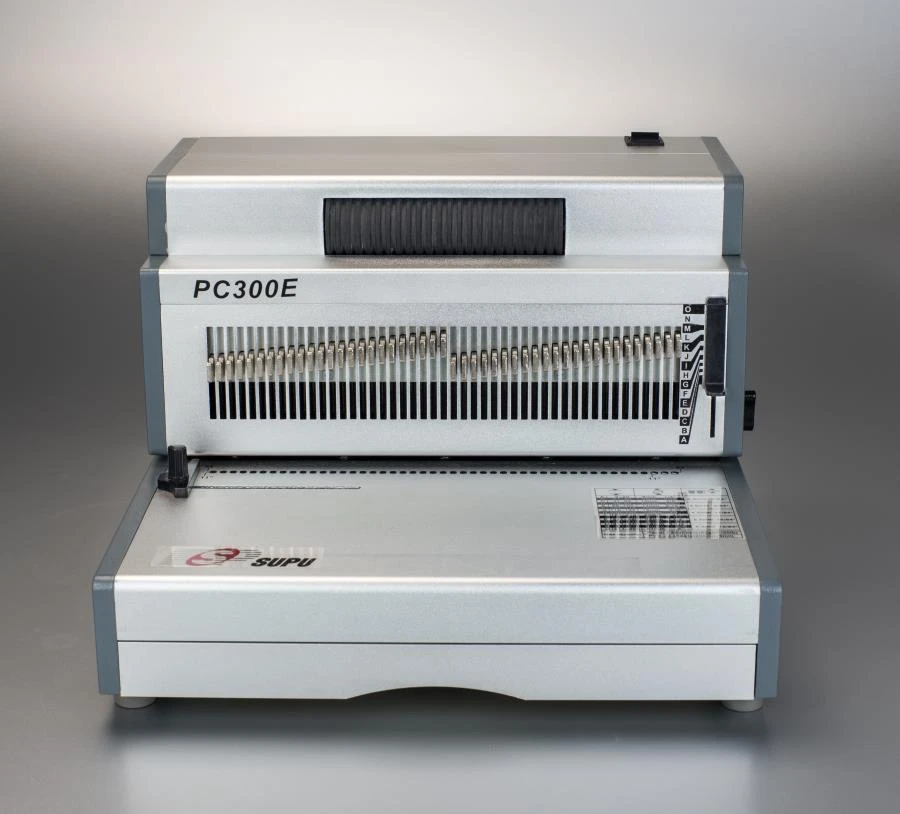

Spiral binder PC300E

- group name

- Spiral Binding Systems

- Min Order

- 1 set

- brand name

- SUPU

- model

- PC300E

- Nearest port for product export

- NINGBO, SHANGHAI

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

- Export mode

- Have the independent export and import right

- update time

- Sat, 28 Feb 2026 05:31:35 GMT

Paramtents

Power Electricity

Width 300mm

Pitch 6.287mm

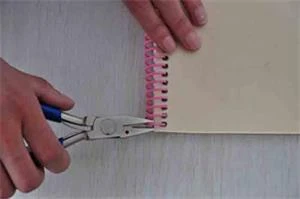

Hole type round, oval

Punching thickness 25sheets

Binding Thickness 180sheets

Number of punch pins 47

Disgagement punch pins 47

Packging & Delivery

-

Min Order1 set

Briefing

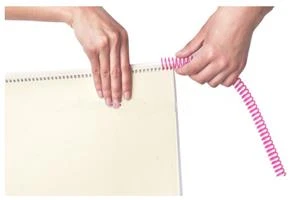

electric punching and electric binding

desk-top , for office and factory use

CE,ETL,SAA,CB,RHS,ISO

desk-top , for office and factory use

CE,ETL,SAA,CB,RHS,ISO

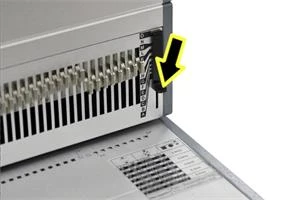

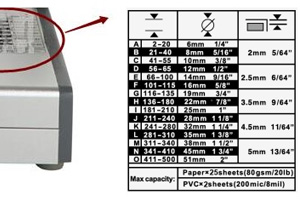

Detailed

Document measure to determine which comb size to be used All aluminium construction make it durable and many years worry free High capacity waste container requires emptying less frequently