Search This Supplers Products:Binding MachineBinding machinePerfect binderPaper cutterLaminating MachineShredder

What To Look For When Buying A Binding Machine

What To Look For When Buying A Binding Machine

Considering splashing out on a new binding machine at work? Or perhaps you don’t currently have one but you’ve decided it’s time you finally bought one? There are a fair few options available to you and it’s important to get the right one to ensure your documents look as professional as possible.

There are a few things to consider before you buy, so here’s what to look for when buying a new binding machine…

What type of binding do you want?

This is probably the first thing you need to think about. Not every type of binding requires a machine. For example, slide binders and binding screws can be done by hand, but for pretty much every other type, you’ll need a binding machine.

If you’re using wire or comb binders then there are various machines you can choose from depending on how much material you want bound and how much you want to spend.

If you want thermal binding, then you have no choice but to use a machine as the material is bound using heat. There are different thermal binding machines available, some of which allow you to bind several documents at once.

2:1 or 3:1 pitch?

When buying a wire binding machine, you need to decide whether you want a 2:1 or 3:1 pitch. What’s the difference, you say?

Well it’s all about how far apart the looped wire is spaced, and this affects how much paper the binding can accommodate. 2:1 pitch means that there are two holes per inch, which usually works out as 16 holes for A5 and 23 holes for A4. 3:1 pitch, as you can probably guess, is three holes per inch, making the wire more tightly bound.

Whilst, typically, wire binding machines come in either 2:1 or 3:1 pitch variants, you can also buy machines that do both, just like this one here.

How much binding are you going to do?

How much binding you intend on doing will go a long way in determining which binding machine you buy. For example, if you’re only binding the odd document then you might be better off choosing a cheaper option, but if you’re going to be doing a lot of binding on a regular basis then it will pay to go for a more comprehensive machine.

If we’re looking at plastic comb binding machines, then the one below is a good starter option if you’re not going to be doing a huge amount of binding.

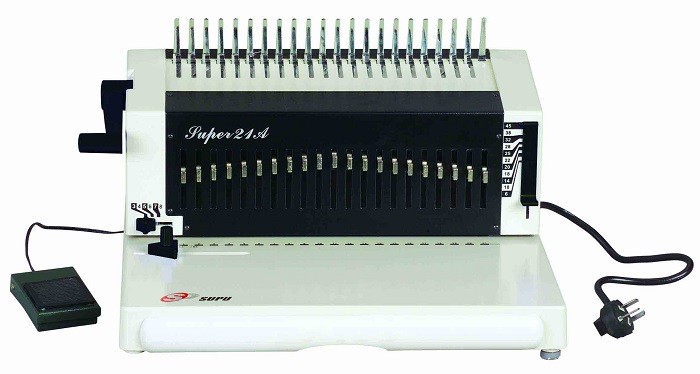

However, if you’re going to be doing a higher volume of binding, then you might want to plump for something a little more heavy duty, such as the following machine…

Electric or manual binding machines

This follows on nicely from the previous point. With wire or comb binding, you can choose from either manual or electric binding machines, and the choice between the two may well be dictated by how much binding you have to do.

If you don’t have much to do then a manual machine should be fine, but if you have a large amount of binding, an electric binder may be better. An electric machine may also be better if you’re binding a thick document, saving you the extra effort of punching the holes. Manual machines, however, might be the better option if you don’t have easy access to a mains socket to plug in an electric machine.